| |

| Grinding it Out | April 2, 2001 |

| by James F. Vedder | |

Making a mirror the old-fashioned way

![[image]](https://archive.archaeology.org/news/jpegs/mirrors1.jpeg)

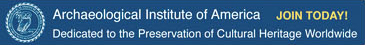

Cypriot ship painted on a modern pot shows clearly on polished obsidian surface. (James Vedder) |

Among the intriguing finds at the Neolithic site of Çatalhöyük in central Anatolia are a few polished obsidian artifacts believed to have been used as mirrors. In a letter in response to an article, "The World's First City" (March/April 1998), which mentions the obsidian mirrors, P.H.M. Hawley wrote, "to make such a mirror requires considerable technology in a sense. To grind a flat surface and then achieve a true polish is not easy" (May/June 1998, p. 11). In an accompanying comment, Orrin Shane (an author of the original article and a curator at the Minnesota Museum of Science) said of the Çatalhöyük mirrors, "Their exceptional planar surfaces are highly polished and reflect a sharp image." I was curious just how difficult it would be and how long it would take to make an obsidian mirror.

In December 1999, I started to fashion a small one by hand, using various readily available materials (some artificial) to grind and polish a broken obsidian nodule. A fragment of concrete sidewalk provided the rough surface for the initial grinding. Once there was a flat surface, I continued, using in order, the side of a discarded abrasive wheel, a fine whetstone, and a fine clay slip on a piece of plate glass. The result was a nearly flat polished area that produced an excellent reflection. After this first success, I used three more obsidian nodules and an obsidian lump with conchoidal surfaces that had lost their luster during long exposure, grinding and polishing them with materials such as granite, quartzite, sandstone, slate, marble, sand, fine-grained stone, clay, and wood ash. The most used for grinding were granite, sand, sandstone, and the fine-grained stone. The fine grained stone gave a fairly good polish, while the others were used briefly to verify that a wide range of materials are effective in the process. I observed the sun's reflection and examined the obsidian surface with a 10x hand lens to evaluate the progress of the grinding and polishing and took great care to keep the surface clear of extraneous material to reduce the possibility of generating scratches. I have yet to explore fully various possible final burnishing, buffing, and polishing procedures. The wood ash was briefly tried as a final polishing agent, but it was probably too fine-grained to improve the existing state of the polished surface with out the expense of an inordinate amount of time. Materials for grinding and polishing comparable to those listed above can be found in Turkey.

The largest mirror surface I produced is about 4 by 6 centimeters (1.6 by 2.4 inches). With experience, one could probably select an optimum set of materials to expedite the creation of a mirror surface. Since achieving the final polish may take the longest time, I can not estimate now the time required to make a mirror.

All of the mirrors produced good images, and all were slightly convex as expected from manual grinding in which linear and rotary motions result in greater pressure being applied around the perimeter of the surface. The only technical reference that I have seen on an obsidian mirror from Çatalhöyük states that it is slightly convex. With special preparation of a core and great care during the grinding process, one could probably make a nearly flat mirror with no obvious distortions in the image.

![[image]](https://archive.archaeology.org/news/jpegs/mirrors2.jpeg)

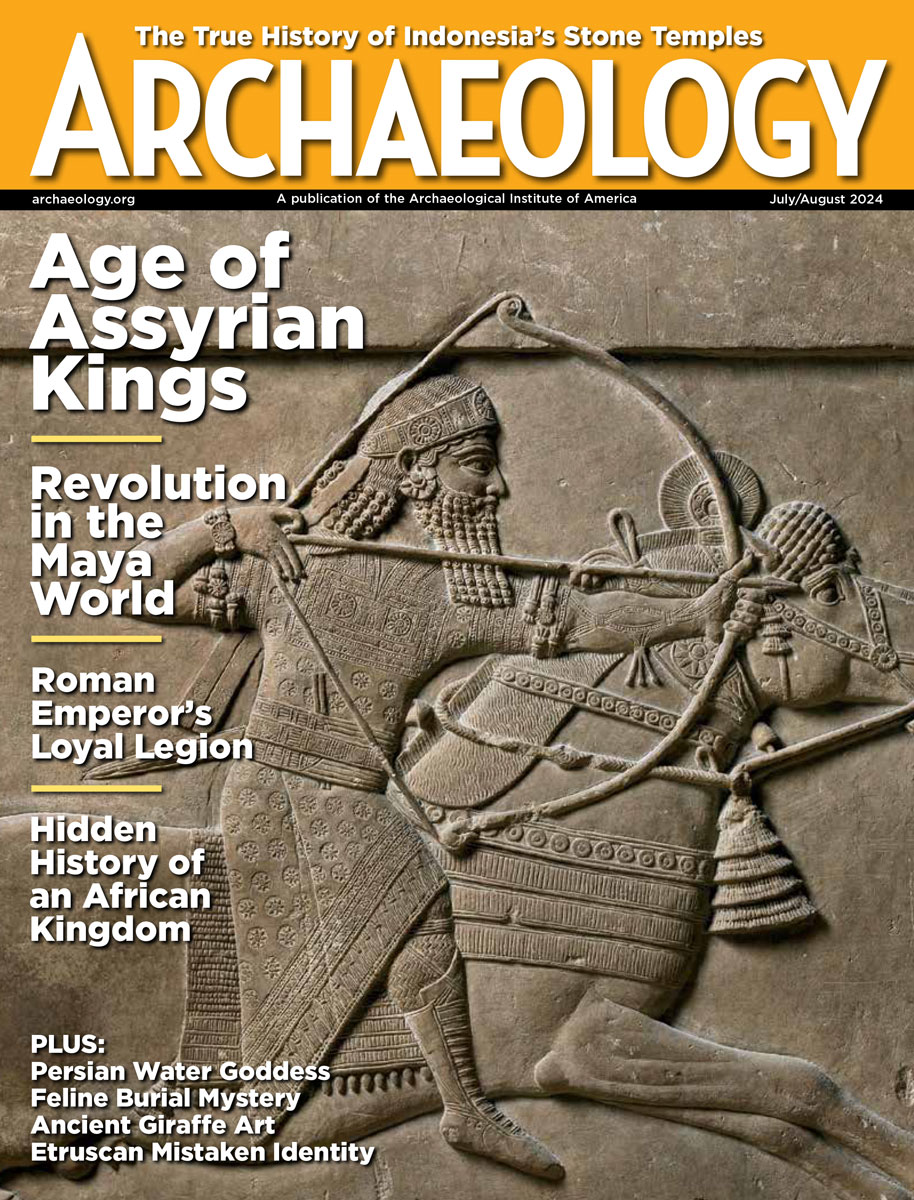

"STOP" image is reflected in experimental obsidian mirror. (James Vedder) |

During my stay at Çatalhöyük in August 2000, I collected information from unpublished notes and speaking with those at the site who had any familiarity with obsidian and grinding stones. I was able to see eight of the Çatalhöyük mirrors. Three each were in the Archaeological Museum of Konya and the Museum of Anatolian Civilizations in Ankara. Dim lighting and glass cases made it difficult to discern details of fabrication. Two in storage at the Konya museum could be inspected close-up. Their faces were slightly convex, as I had suspected; but they were badly scratched, probably from post-manufacturing usage and disposal.

Pictures of at least six obsidian artifacts from Çatalhöyük were published and claimed to be mirrors by the site's first excavator, James Mellaart, who dug there in the 1960s. Naomi Hamilton (a participant in the current efforts at the site) in her unpublished inventory of artifacts from Çatalhöyük held in the Konya and Ankara museums lists 11 items as mirrors or possible mirrors. Those shown by Mellaart are in this list. I have verified that eight of the 11 objects are mirrors and rejected two. One of these two, described by Hamilton as possibly a broken mirror with grinding marks, has linear sets of abrasions at several angles that have obliterated the luster on 60 percent of the surface but have not flattened it. The other, described as a questionable mirror fragment or flake, is a long, thin curved piece lacking luster. The eleventh item, in storage at the Konya museum, is possibly the beginnings of a mirror in the early stage of grinding a core to produce a flat surface.

What purpose did they serve? The conventional answer given by Mellaart is for a woman to view her application of make-up, but few obsidian mirrors have been found and these only in the middle occupation levels at Çatalhöyük. Various alternative uses have been suggested, some practical (illuminating rooms or shafts, starting fires, reflecting sunlight for a compact seasonal calendar, or signalling) and some spiritual (viewing one's soul or performing special rites). No mirrors have been found in the recent excavations, under the general direction of the University of Cambridge's Ian Hodder; but only the group from the University of California, Berkeley, is working at the levels IV to VI in which Mellaart discovered the objects.

In conclusion, there is abundant archaeological evidence for grinding and polishing stone to make tools and ornaments. No technological innovation was required before obsidian mirrors could be produced. While the only raw materials available locally to the ancient inhabitants of Çatalhöyük were clay, lake-bed marl, grasses, and animal hide, at some distance, the Tarus Mountains to the south and several volcanoes in other directions, could have been the sources ofmaterials suitable for grinding and polishing obsidian.

© 2001 by the Archaeological Institute of America archive.archaeology.org/online/news/mirrors.html |

Advertisement

Advertisement